Improve Efficiency With Airleader Compressor Management

- Home

- Improve Efficiency With Airleader Compressor Management

Improve Efficiency with Airleader Compressor Management

The Compressed Air and Gas Institute (CAGI) publishes compressor performance data for participating OEMs. This information is especially relevant when evaluating the efficiency of Variable Speed Drive (VSD) compressors.

Understanding VSD Compressor Efficiency

A typical characteristic of a VSD compressor is that it incurs an additional energy cost of approximately 3–5% compared to a fixed-speed compressor when operating at full load, due to inverter losses. Additionally, the screw element design significantly influences the overall energy characteristic of the VSD.

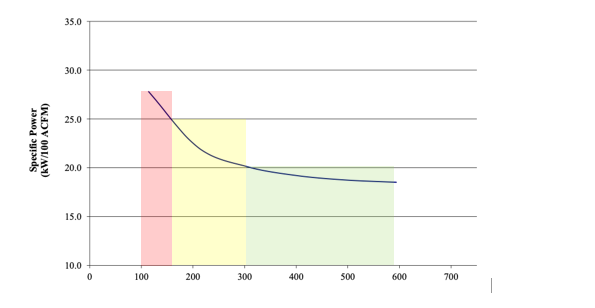

For example, consider this sample VSD compressor with a maximum output of approximately 600 CFM and a minimum output of around 100 CFM.

While the compressor’s specific power is acceptable between full load (600 CFM) and half load (300 CFM), it becomes increasingly inefficient below 300 CFM. In this lower range, the specific power can exceed 25 kWh/100 CFM, making operation in this region highly inefficient.

Although VSD compressors are marketed as having a wide operating range (e.g., 100–600 CFM), the efficient operating range is typically between 300 and 600 CFM.

Optimizing Operation with Airleader Compressor Management

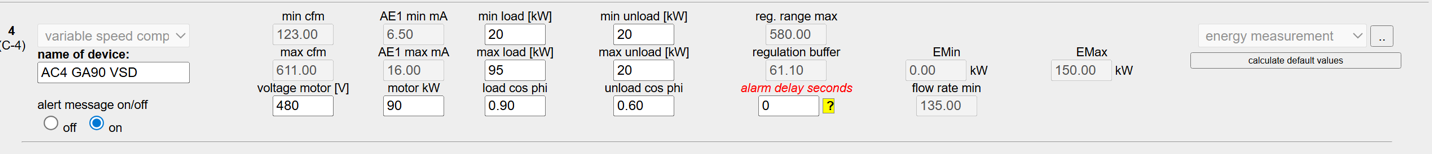

To avoid inefficient operation, the Airleader Master Controller can be programmed to limit the VSD compressor’s usage to its efficient operating range.

Step-by-Step Configuration:

- Set VSD Min/Max Flow Limits:

- Program the controller with the VSD’s physical limits:

- Min Flow Rate: 100 CFM

- Max Flow Rate: 600 CFM

- Program the controller with the VSD’s physical limits:

- Define the Efficient Operating Range:

- Program the minimum efficient flow at 300 CFM.

- Program the maximum efficient flow at 580 CFM (to maintain a buffer before reaching maximum capacity).

- Dynamic Compressor Switching:

- If flow demand drops below 300 CFM, the VSD will operate in this inefficient range only for a limited time (default is 200 seconds), after which the Airleader will attempt to switch to a more efficient compressor combination.

- Similarly, if demand exceeds 580 CFM, the controller will try to add another compressor to bring the VSD back into its optimal range. Again, the VSD will run in this higher range for a set period (default: 200 seconds) before adjusting the mix.

Key Considerations for Effective Control

For this strategy to work efficiently, the compressed air system must be designed without control gaps. All compressors and controls must be properly sized and coordinated to allow seamless switching between units, avoiding pressure or flow instability.

Summary

By properly programming the Airleader Master Controller, you can ensure that your VSD compressor operates only within its efficient performance envelope, avoiding excessive energy use at low and high extremes. This results in significantly improved overall system efficiency and reduced operational costs.

Programming Airleader Master – VSD